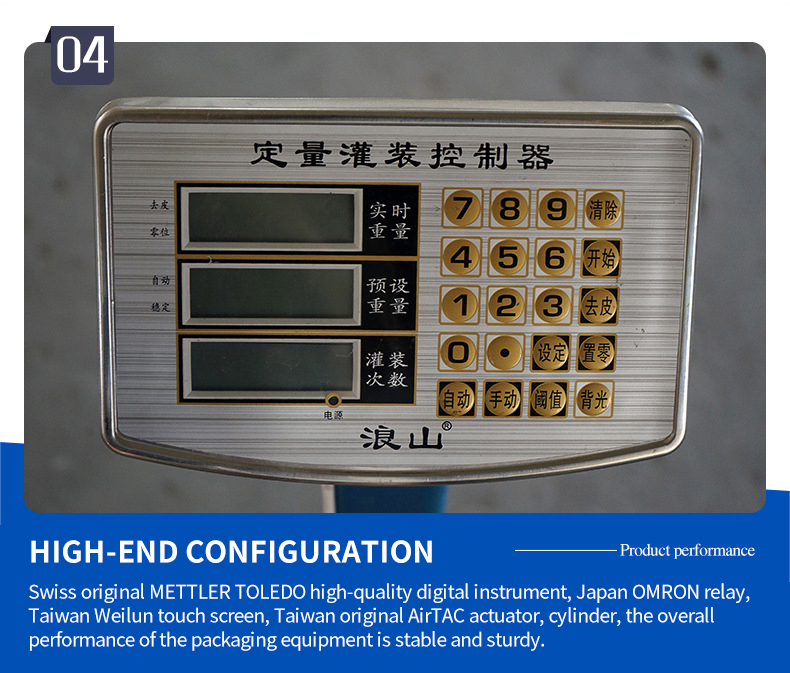

The principle of automatic weighing, filtering and filling machine is to set the measurement by the load cell platform under the control of the microcomputer program. It is a new type of high-tech product integrating machine, point and instrument. It changes the quantitative accuracy of traditional flowmeter-type filling machines and the inability to measure viscous liquids. When filling, the tare weight is automatically removed first, and when the material is injected into the container, a large amount of material is filled first, and then it is corrected and measured at a slow speed and a small dose. The operator needs to put the container into the platform, and the barrel mouth is aligned with the filling nozzle. At this time, the program starts the filling nozzle to automatically descend, and opens the filling valve to feed the material. When the set amount is reached, the filling is automatically stopped, and the filling nozzle rises. filling process. The weighing filling machine is suitable for weighing and quantitative filling of a variety of viscous, non-sticky, corrosive and non-corrosive, foamed and non-foamed liquids.