Model specification: 4DCS-60

Applicable material: Granular material

Rated capacity: 5-60kg

Weighing speed: 1900-2880 bags/hour (40kg/pack)

Display resolution: 10g

Metering accuracy: 0.1% static ≤±, 0.2% dynamic ≤±

Air supply: air pressure: 0.6MP, gas consumption: 0.5m3/h

Power supply: Packing scale: AC220V/50HZ

Conveyor seam bag: AC380V/50HZ

Total power: (0.37*4pcs*7.5)kw

Installation height: 5.2

Dimensions: (6*1.8*5.2)m

Temperature range: -10~40°C

Relative humidity: ≤90%RH (non-condensate)

Total weight: 500KG

Powder weighing and packaging machine, quantitative powder packaging scale

Scope of application

Chemical industry: resins, coatings, pigments, pharmaceuticals, pharmaceuticals, cosmetics, fire extinguishers, plastic powders, etc.;

Abrasives, glass, ceramics industry: abrasives, alumina, porcelain mud, clay mud, glass powder, refractory materials, quartz sand, etc.;

Food industry: sugar, monosodium glutamate powder, salt, starch, milk powder, grain, egg powder, etc.; traditional Chinese medicine

Ironmaking industry: ore, titanium oxide, zinc oxide, casting sand, metallurgical powder super-hard alloy, electromagnetic materials, aluminum powder, various metal powder particles, etc.; other industries: carbon black, co-solvents, activated carbon, pearls, etc.

How to use:

When the operator puts on the bag, the switch is triggered by the way, and the packaging machine begins to automatically complete the process of clamping the bag and discharging the material, and the packaged bag automatically falls off. At the same time, the metering bucket automatically shifts the feeding, when the weight reaches the set value, the replenishment is automatically ended, and when the operator puts on the new packaging bag, the next packaging process starts automatically.

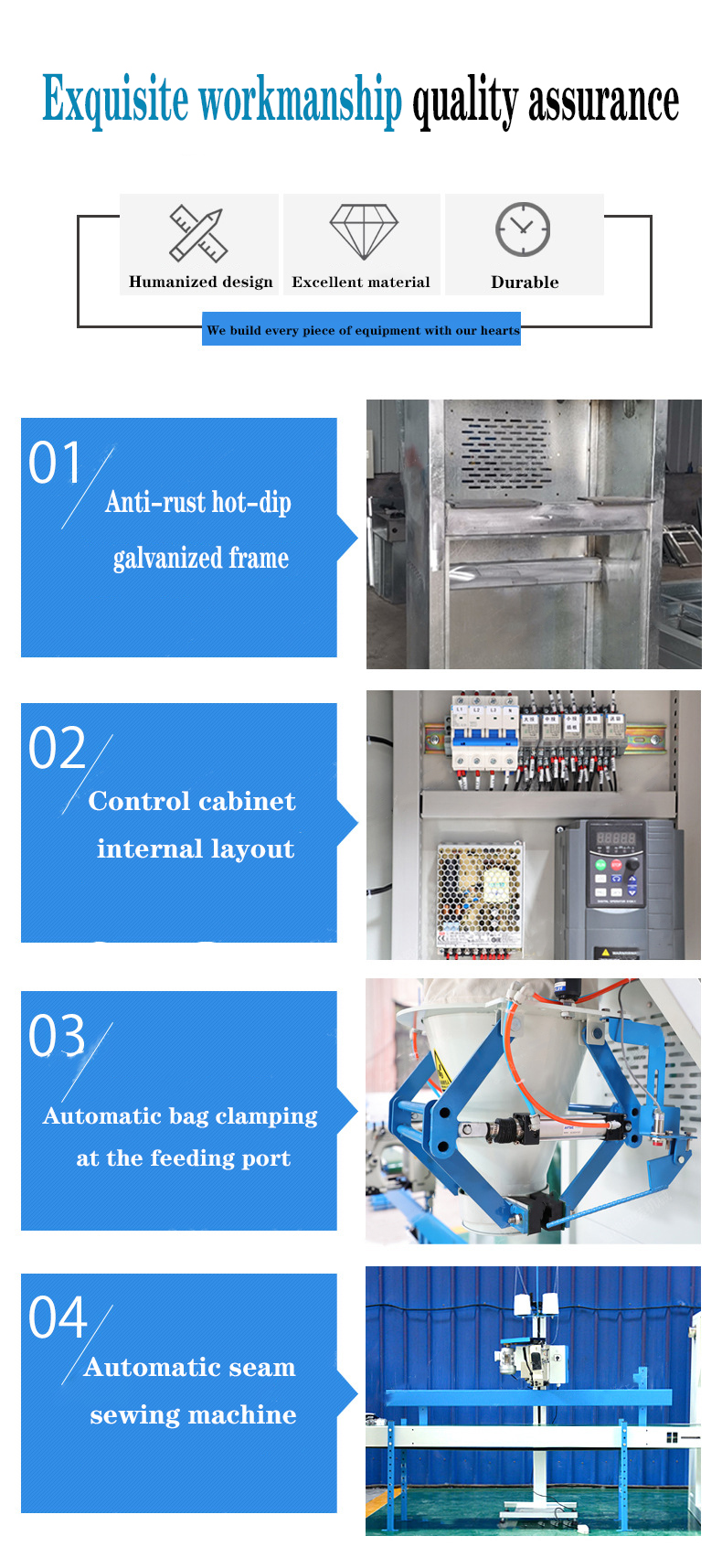

Packing machine features:

1. The use of Chinese digital display is simple and intuitive, the packaging specifications are continuously adjustable, the working state is arbitrarily changed, and the operation is very simple.

2. There are three kinds of feeding methods for choice, high, medium and low, quantitative accuracy and high precision.

3. It has the functions of weighing value setting, storage, modification and so on.

4. With zero setting and automatic zero point tracking function.

5. With the total weight of the package and the number of bags cumulative display function.

6. It has process chain control functions such as weighing, unloading and bagging.

7. With automatic, manual peeling function.

Supporting equipment:

1, the fighter elevator: the material is lifted to the hopper of the quantitative packaging machine, saving manual feeding equipment)

2, stranded dragon: the granular material is transported to the hopper of the quantitative packaging machine, instead of manual feeding equipment)

3, belt conveyor, this machine is to pack the grain into bags and then directly loaded on the car, or transported to the warehouse equipment loading, warehousing

Scope of application:

Quantitative packaging of granular materials in grain, seeds, sesame, fertilizer granules, rubber granules, plastic granules, PP granules, PE granules, inorganic salts, industrial salts, steel powder, white sugar, food granules, metal granules, feed, grease, rice, sugar, food, chemicals and other industries.

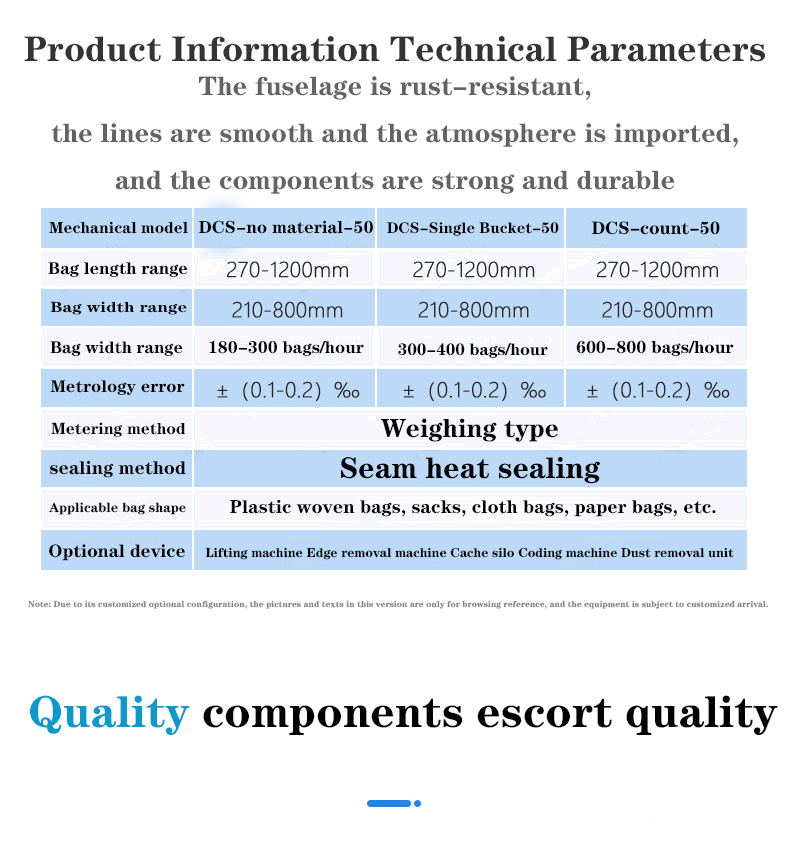

Technical parameters:

Model specification: 4DCS-60

Applicable material: Granular material

Rated capacity: 5-60kg

Weighing speed: 1900-2880 bags/hour (40kg/pack)

Display resolution: 10g

Metering accuracy: 0.1% static ≤±, 0.2% dynamic ≤±

Air supply: air pressure: 0.6MP, gas consumption: 0.5m3/h

Power supply: Packing scale: AC220V/50HZ

Conveyor seam bag: AC380V/50HZ

Total power: (0.37*4pcs*7.5)kw

Installation height: 5.2

Dimensions: (6*1.8*5.2)m

Temperature range: -10~40°C

Relative humidity: ≤90%RH (non-condensate)

Total weight: 500KG